75g Snack Chip Packaging Machine 10 In A Row

time2020/12/12

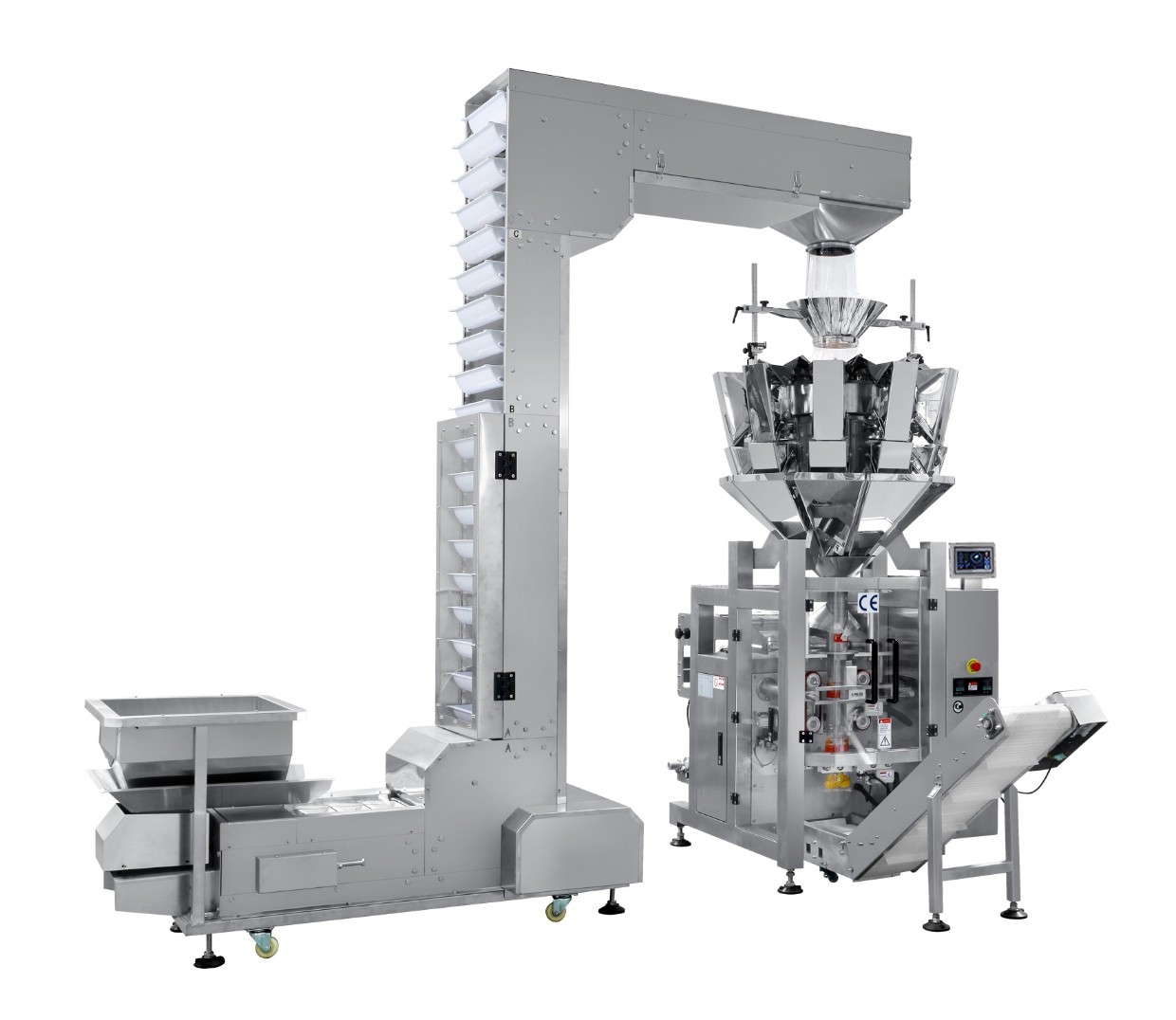

- 10 head vertical packaging combine machine for 75g snack

Combine 10 head vertical packaging machine snack packing line

Application

It is suitable for weighing and packing all kind of snack such us nut,bean,seed etc .

Seed

Nut

Bean

Snack

Machines List

① Vibrating feeder

② Z type Bucket elevator

③ Multihead Weigher

④ Working Platform

⑤ Vertical Form Fill Seal Machine

⑥ Output conveyor

⑦ Metal Detector (OPTION)

⑧ Check weigher (OPTION)

⑨ Collect Table (OPTION)

⑩ Nitrogen Generator (OPTION)

Working Principle

① Filling products into hopper of bucket conveyor on floor;

② Products will be lifted on the top of multihead weigher for feeding;

③ Multihead weigher will automatic weigh according to preset weight;

④ Weighed products will be dropped to VFFS machine for bagging and sealing;

⑤ Finished package will be outputted to metal detector, machine will alarm if with metal, if not will go to check weigher

⑥ Product will be passed through check weigher, if over or less weight, it will be rejected, if not, pass to rotary table

⑦ Products will get to rotary table, and worker put them into paper box

Features

① Fully-automatically procedures from material feeding, weighing, filling and bag-making, date-printing to finished products output;

② High weighing precision and efficiency,with speed as fast as 50 bags per minute;

③ Multi-languages touch screen for various clients, English, French, Spanish, etc;

④ Combine design,small ground occupation,saving more space and cost;

⑤ Double film pulling belt with servo system;

⑥ Designed and Manufactured in accordance with the CE Safety regulations;

⑦ Only control touch screen to adjust bag deviation. Simple operation.

Specifications

|

Model

|

M10P420

|

||

|

Speed

|

10-50 bags/min

|

||

|

Accuracy

|

0.2-1.5g

|

||

|

Weight range

|

10-800g

|

||

Bag size | 50-280mm(L),80-200mm(W) | ||

Bag type | Pillow bag,pillow bag with gusset | ||

Bag material | Laminated film,Mono PE film | ||

Film thickness | 0.04-0.09mm | ||

Weight hopper volume | 1.6L | ||

Control panel | 7" touch screen | ||

Air comsumption | 0.8 Mpa,0.4 m³/min | ||

Power supply | 220V 50/60 HZ,15A,4000W |

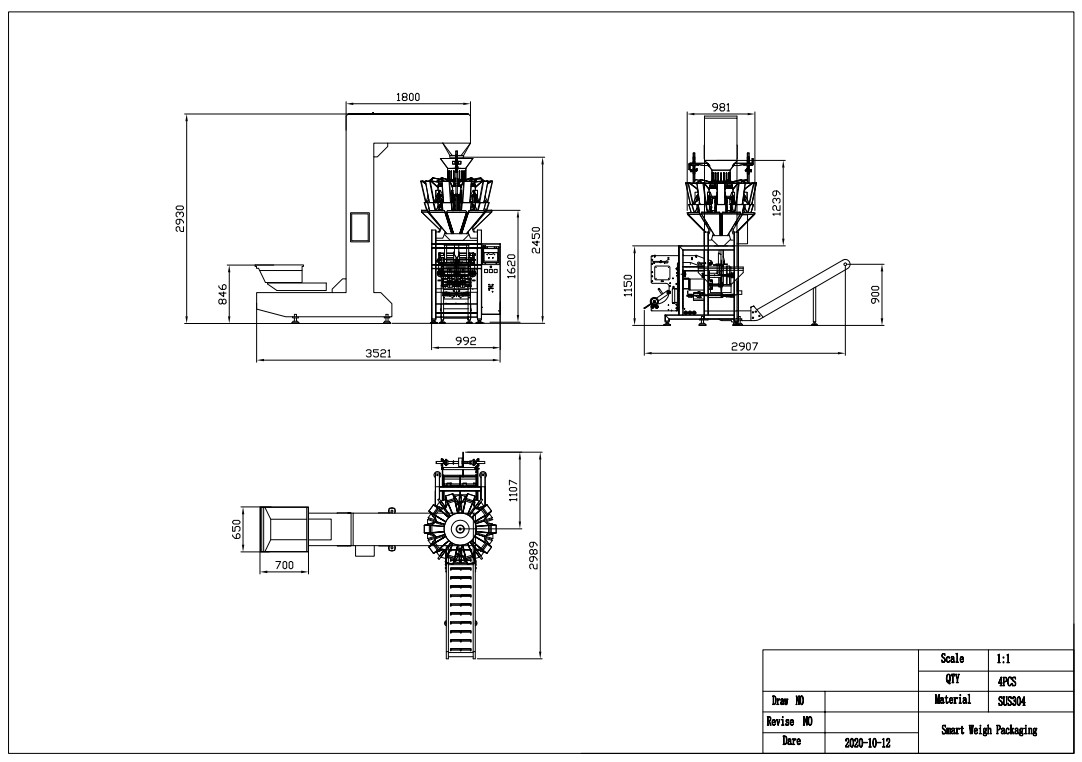

System Drawing